Mosfetguide

| What is a Mosfet and what use is it in airsoft? |

|

A Mosfet (metal oxide semiconductor field effect transistor) is an electronic component that is used to control currents. A Mosfet always has at least 3 connections: 1. Gate (control electrode) 2. Drain 3. Source The way it works is explained simply: the source current, i.e. the connected battery, is applied to connection 3 (source). The Mosfet prevents the current from flowing to terminal 2 (drain) unless a certain voltage is applied to terminal 1 (gate). This control voltage is much lower than the source current. A Mosfet divides the current into two "flows", so to speak 1. Main voltage - goes directly to the Motor 2. Secondary voltage - is still conducted via the switch unit A Mosfet therefore has the effect that the switch unit (trigger unit) is protected by a lower current flow (voltage) and is therefore only used as a signal transmitter when the trigger is pulled, so that the main current flow from the battery to the Motor is released and a shot can be fired. Another advantage is the improved response behaviour, as the internal resistance of a Mosfet is significantly lower than with the contacts of the switch unit. In addition, the metal contacts are subjected to far less stress due to the lower current flow, so that a possible source of error (defective contacts due to carbonization) can be delayed. With a fully automatic AEG, there is also the advantage of a higher rate of fire (ROF) due to the lower resistance of the current flow |

| Mosfet types: |

|

Before installing a Mosfet, you should always check whether the required space is available in the gun. For AEPs, for example, micro Mosfets should always be used, as they take up the least space and can still accommodate a battery. But even with long guns such as AR15/M4 models, you should check exactly how much space is still available to accommodate the battery if you want to install a MOSFET. Furthermore, the wiring instructions, which are usually enclosed in paper form, must be observed so that there is no short circuit or similar after installation (unless the MOSFET is already wired from delivery) |

| "Regular" Mosfet: |

|

The standard MosfETs are larger compared to the micro variants, which on the one hand means a higher load capacity with corresponding current flows. These MOSFETs are more suitable than the micro MOSFETs, especially when using stronger Springs from M140, as the load on the components on the board is lower. On the other hand, these MOSFETs are more user-friendly, especially for beginners in terms of soldering the cables, as the soldering points on the MOSFET board are larger, making installation easier.

Nowadays (01/2023), this type of Mosfet is hardly used anymore and has been largely replaced by the drop-in Mosfet (EFCS), as these systems do not have programmable additional functions |

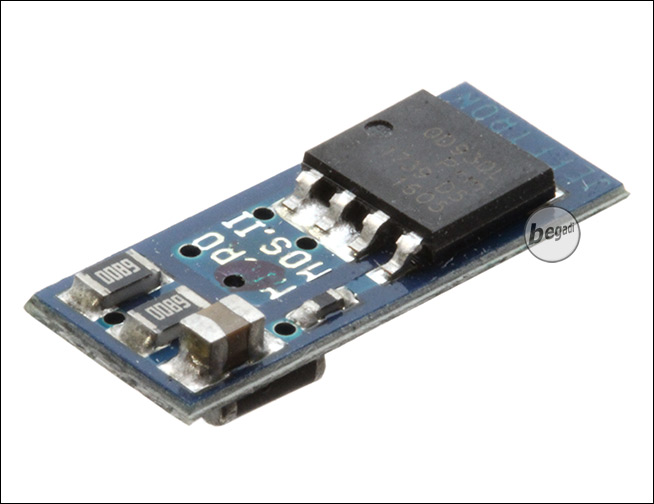

| Micro Mosfets: |

This design is particularly suitable for models where space is at a premium. These include, above all, AEP guns and electrically operated machine guns. Due to their compact design, they have little to no additional functions and are designed for maximum spring strengths of M120-M130. The most common representative of Micro Mosfets is the JeffTron Micro II

|

| Drop-In Mosfets / EFCS: |

|

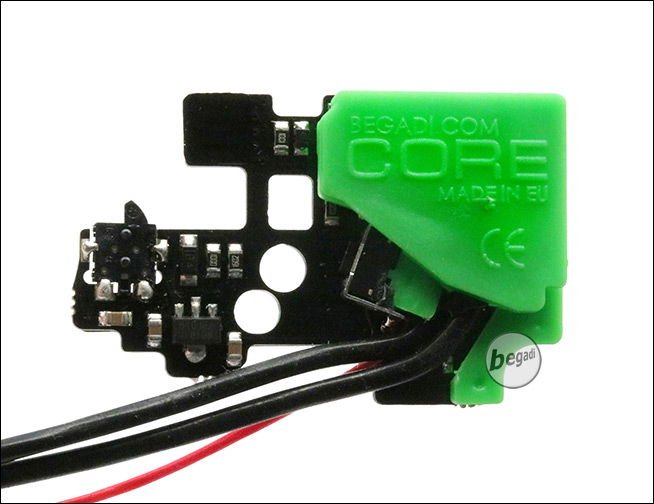

Drop-in Mosfets are installed instead of the switch unit and are ultimately a hybrid, as the Mosfet is incorporated into the switch unit. As a rule, no soldering skills are required here, as these MOSFETs are usually completely pre-wired. A common representative was the JeffTron Basic Internal Mosfet, which was available for both V2 and V3 Gearboxes. In the meantime (as of 01/2023), drop-in MOSFETs have been almost completely replaced by EFC systems, as these allow far more setting options |

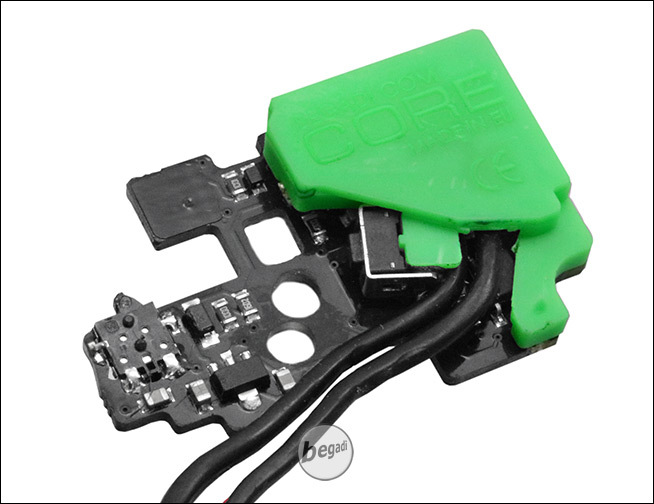

| The BEGADI CORE EFCS: |

In addition to the classic Mosfets, so-called EFC systems (Electronic Fire Control System) have also been around for several years. These are advertised by the various manufacturers with a wide variety of designations (EFCS, ETU, EFC, GCU etc.), although the basic idea of all systems is the same: in addition to the functions of a Mosfet, EFC systems are intended to monitor the firing cycle of an electric airsoft and protect the system from malfunctions, e.g. due to insufficient battery voltage or a short circuit.

The Begadi Core is an in-house development by BEGADI and is only available from us. It was specially developed and built for the German market and is installed in almost all new BEGADI guns. The functions of the BEGADI CORE EFCS include the following:

Further functions are available for other systems:

We have summarized further information on the Begadi CORE EFCS on a separate page: https: //www.begadi.com/core-mosfet/

|

| Difference - mechanical and optical EFCS systems: |

A distinction is made between two types of EFC systems:

in mechanical systems, all movements of the firing cycle are recorded via mechanical components and forwarded to the electronics. Optical systems use light sensors for this purpose, which are used to read out the functions of the system. Another key difference is often the way in which the safety is adjusted: with mechanical EFCS, this is usually still done via the factory-installed components (with V2 Gearboxes via the Safety Lever). With optical systems, on the other hand, the trigger can be fully depressed even in the externally secured state. In this case, the safety is provided by the built-in light sensors, which read the position of the Fire Selector via a sticker on the Selector Plate. Furthermore, most mechanical EFC systems usually consist of just one component or circuit board, whereas the optical systems usually consist of two circuit boards that are plugged together inside the Gearbox. On the one hand, this ensures less light influence on the light sensors, while on the other hand there are additional sensors on the upper circuit board that are essential for the functionality of the system

The advantages and disadvantages of the two systems in direct comparison are marginal and are based more on personal preferences, e.g. with regard to the implementation of the fuse or the reprogramming of the functions. We have summarized the key data of the mechanical and optical EFC systems below as a small decision-making aid: Mechanical systems

Optical systems

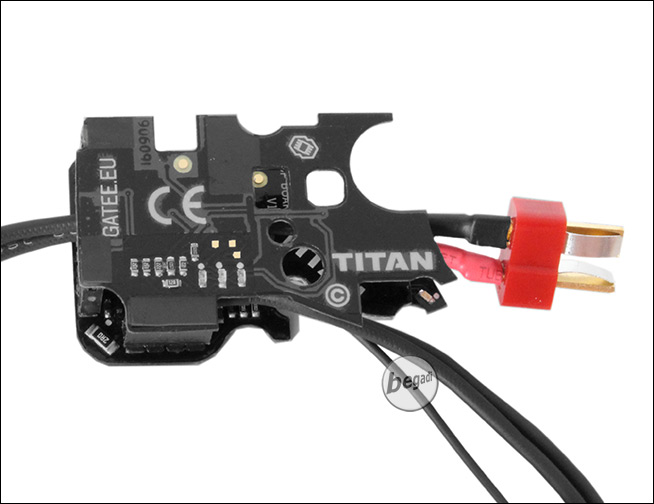

Setting the additional functions of an EFCS The above-mentioned functions can be set either via so-called trigger commands or, in the case of Gate Titan or JeffTron Leviathan, via an app. When setting via the Triggers, a small card is usually included in the scope of delivery, on which the various functions with the corresponding trigger commands can be found. A predefined number of trigger operations is used to navigate through a kind of menu in the EFCS, which is confirmed by vibrations from the Motors. Optical systems can be set via an app, which is the more convenient way for many players, as the settings can be changed with just a few "button presses" and the design is clearer. In this case, the gun is connected to the mobile device (smartphone, tablet) via the battery connection (a data cable is usually included), then the corresponding app is started and the "programming" can begin

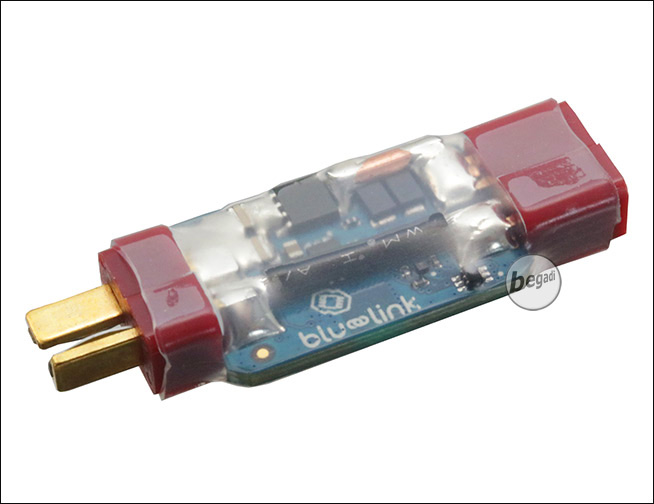

GATE Blu-Link - reading out data The Blu-Link from GATE is an adapter that can be operated via Bluetooth and is connected to the gun's battery connection. This can then be used to read out numerous system data from the EFCS installed in each case, such as the current required by the motor, the temperature of the motor, the firing processes already carried out by the system, but also the duration of a firing cycle. In addition to the adapter, the free "Gearbox Control Station" app from GATE is required on the corresponding mobile device for this

|

| Further information on retrofitting an EFCS: |

|

When retrofitting an EFCS, there are a few things that should be considered before purchase that are important for a successful self-installation. When selecting the EFCS, in addition to the appropriate version for the corresponding Gearbox shell (e.g. whether for V2 or V3 Gearbox), attention should be paid to the direction of the wiring. All EFCS are wired ex works, so you should first pay attention to whether the battery should be placed in the Stock (Rear-wired) or in the Front (Front-wired). As a rule, all M4/M16 models are Rear-wired and G36 models are Front-wired. Furthermore, the circuit board of the EFCS should fit into the Gearbox shell without any tension or adjustments. If this is not the case, malfunctions or similar faults may occur. For EFCS with two circuit boards, you should also ensure that the upper Gearbox shell does not press on the upper circuit board and possibly damage it. In addition, optical systems are susceptible to grease and dirt due to the built-in light sensors, which is why excessive greasing of the Gears should be avoided. Special attention should also be paid to the functionality of the fuse. It is a good idea to additionally glue the sticker on the Selector Plates with superglue so that it does not fall off. With mechanical systems, on the other hand, it is also important when installing the Sector Gears to ensure that the control cam on the underside does not rest on the control cam of the EFCS when it is inserted, which could damage it. Furthermore, the manufacturer's specifications regarding the maximum voltage of the battery (e.g. maximum 11.1V LiPo or 14.8V LiPo), the battery type (LiPo, LiFePo, NiMh) or the maximum spring strength to be installed must be observed |

| Guarantee & warranty: |

|

When installing a Mosfet, the Gearbox usually has to be opened in order to re-route the cables. An exception to this is the V6 and V7 Gearbox, where the EFCS is screwed on from the outside and its removal does not require the Gearbox shell to be opened. Please note that opening the Gearbox on your own will void the warranty. In order not to lose this, our workshop offers an installation service for Mosfets and EFC systems. We are also happy to help with problems with the installed system and offer the possibility of troubleshooting through our workshop, provided the airsoft gun and the associated EFCS were purchased from us in the store |

| Further assistance: (Video instructions) |

|

Below we have listed further assistance in the form of videos from our review partners on a wide variety of EFC systems. In addition to the installation, the functions and their programming are also discussed here - BEGADI CORE EFCS (V2 version) - Airsoft Systems ASCU (0.5 joule version) - GATE Titan Video (V2 version) - GATE Aster (V2 version) - JeffTron Leviathan (V2 version) - JeffTron Leviathan Optical (V2 version) - Perun Optical (V2 version) - Perun Hybrid (V2 version) |