Begadi PRO 50° "GBB5" Flat Hop Bucking / Rubber for GBB & Hybrid Barrels -green-

Other interesting articles:

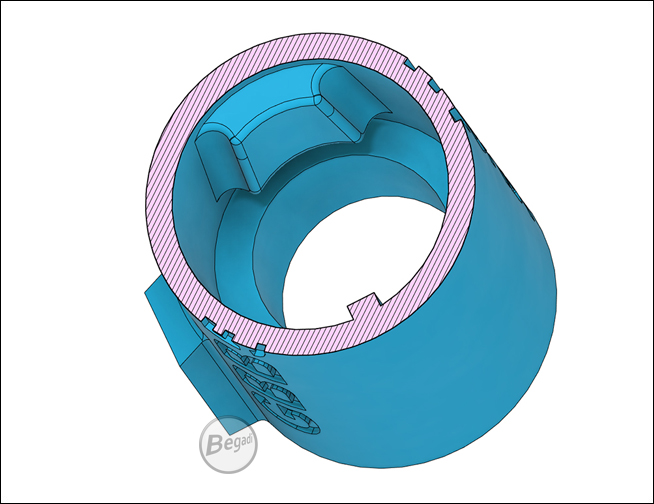

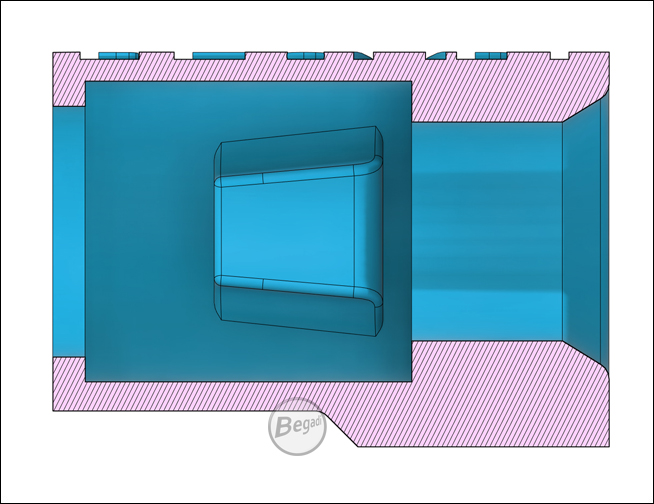

The GBB5 series are newly developed HopUp Buckings / Rubbers from Begadi, designed in Germany!

These are specially designed for GBB weapons and HopUp units and have some special features to increase the range and reduce the dispersion:

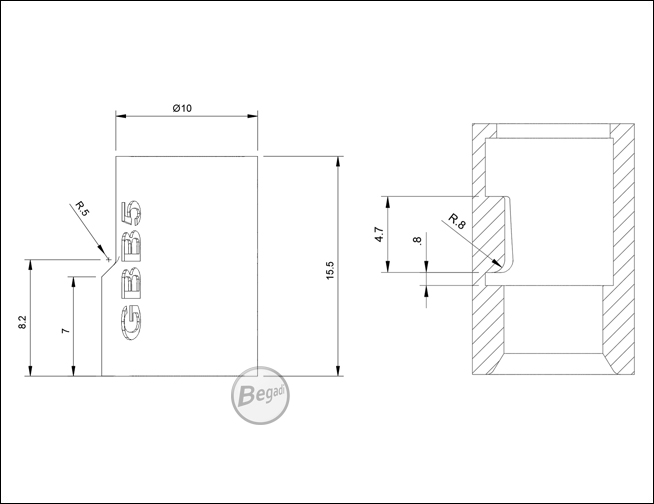

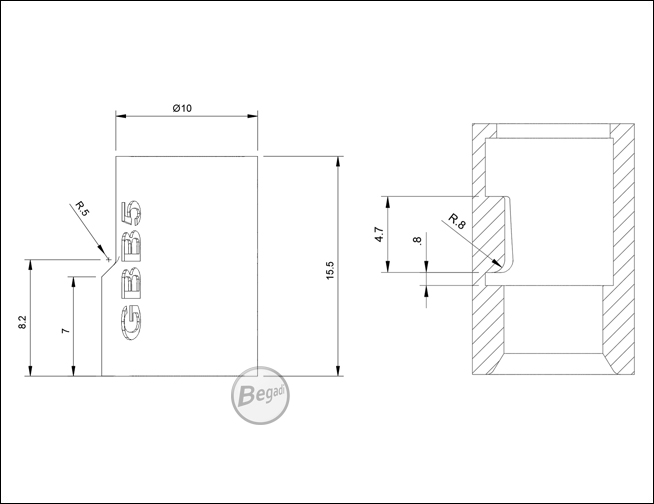

Patch:

Our patch of the GBB5 Bucking has a radius of 2,5mm (5mm diameter). This is therefore smaller than the BB itself and thus ensures accurate centering of the BB in the barrel.

Likewise, the BB is guided straight during firing to prevent runaways to the side. To generate a constant hop effect, the braking effect decreases in the front area.

To ensure the best possible compatibility with the tensioners available on the market, the patch was equipped with a large radius to the sides.

Seal:

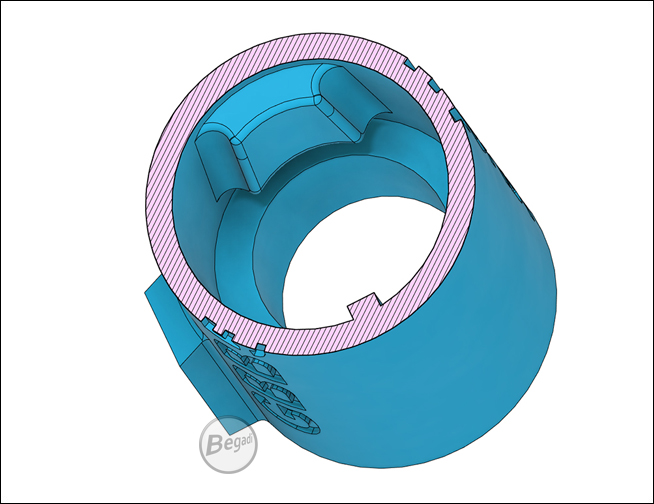

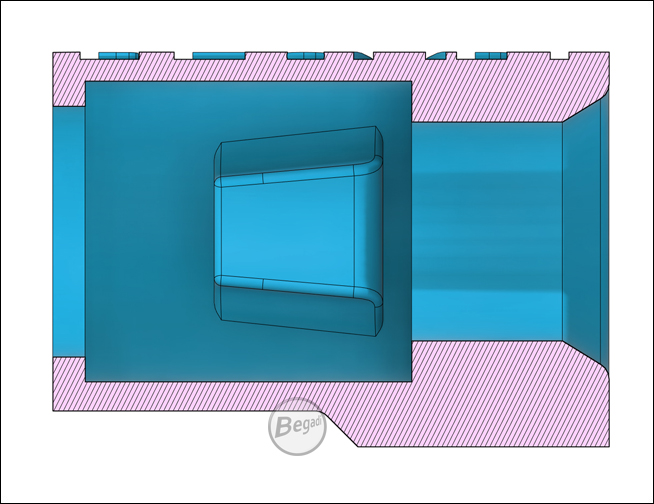

Our GBB5 bucking is 0.2mm larger in diameter than some original bucking when installed. This means that the rubber is slightly pressed against the wall of the HopUp Unit during installation, which results in a very good seal.

The rear diameter (seal to the nozzle) is 6.1mm with a tolerance of 0.05mm and is therefore slightly larger compared to the VSR version. This is necessary to keep the nozzle tight on the one hand, but at the same time to prevent the nozzle from jamming in the bucking.

Barrels:

Our bucking is compatible with open GBB barrels as well as hybrid barrels with bridge.

Durability and Wear:

All our Begadi PRO Buckings are made of a very robust and durable rubber compound. This keeps the set HopUp effect constant over a long time and wears out much slower than conventional rubbers.

You also don't have to worry about the rubber cracking on the patch during disassembly or maintenance. However, you should exercise some caution when pulling it off. Please note the correct choice of hardness for your weapon (energy and bullet weight). If a too soft rubber is selected here, the wear increases!

Marking/Hardness:

To be able to distinguish our buckings, the respective version is directly marked. The rubber compound (hardness) is reflected in the color: 50° green - 60° blue. Thus, it is immediately apparent which version it is. Depending on the temperature, tensioner and ball weight, a 50° or 60° is required. Please note that a rubber compound becomes slightly harder when cold.

The choice of hardness:

Due to the variety of different HopUp Units and Tensioners on the market, we unfortunately cannot say exactly which hardness will work better in your GBB.

Here is an example: A WE HiCapa has a slightly flatter tensioner installed, with this for 0.30g BBs a 60° bucking is required. An Army Armament R17, on the other hand, develops a little more pressure via the tensioner, so the 50° is already sufficient. We recommend testing both hardnesses to find out which hardness works more consistently in your HopUp unit.

Shooting in:

Like all other available buckings on the market, ours need to be shot in. A constant HopUp effect is achieved after approx. 200 - 400 shots. (Depending on energy and bullet weight)

Avoid setting too much hop with the first 2 magazines, as the patch must first work its way in. If possible, use a gas with a low silicone content, as this can greatly reduce the hop-up effect.

These are specially designed for GBB weapons and HopUp units and have some special features to increase the range and reduce the dispersion:

Patch:

Our patch of the GBB5 Bucking has a radius of 2,5mm (5mm diameter). This is therefore smaller than the BB itself and thus ensures accurate centering of the BB in the barrel.

Likewise, the BB is guided straight during firing to prevent runaways to the side. To generate a constant hop effect, the braking effect decreases in the front area.

To ensure the best possible compatibility with the tensioners available on the market, the patch was equipped with a large radius to the sides.

Seal:

Our GBB5 bucking is 0.2mm larger in diameter than some original bucking when installed. This means that the rubber is slightly pressed against the wall of the HopUp Unit during installation, which results in a very good seal.

The rear diameter (seal to the nozzle) is 6.1mm with a tolerance of 0.05mm and is therefore slightly larger compared to the VSR version. This is necessary to keep the nozzle tight on the one hand, but at the same time to prevent the nozzle from jamming in the bucking.

Barrels:

Our bucking is compatible with open GBB barrels as well as hybrid barrels with bridge.

Durability and Wear:

All our Begadi PRO Buckings are made of a very robust and durable rubber compound. This keeps the set HopUp effect constant over a long time and wears out much slower than conventional rubbers.

You also don't have to worry about the rubber cracking on the patch during disassembly or maintenance. However, you should exercise some caution when pulling it off. Please note the correct choice of hardness for your weapon (energy and bullet weight). If a too soft rubber is selected here, the wear increases!

Marking/Hardness:

To be able to distinguish our buckings, the respective version is directly marked. The rubber compound (hardness) is reflected in the color: 50° green - 60° blue. Thus, it is immediately apparent which version it is. Depending on the temperature, tensioner and ball weight, a 50° or 60° is required. Please note that a rubber compound becomes slightly harder when cold.

The choice of hardness:

Due to the variety of different HopUp Units and Tensioners on the market, we unfortunately cannot say exactly which hardness will work better in your GBB.

Here is an example: A WE HiCapa has a slightly flatter tensioner installed, with this for 0.30g BBs a 60° bucking is required. An Army Armament R17, on the other hand, develops a little more pressure via the tensioner, so the 50° is already sufficient. We recommend testing both hardnesses to find out which hardness works more consistently in your HopUp unit.

Shooting in:

Like all other available buckings on the market, ours need to be shot in. A constant HopUp effect is achieved after approx. 200 - 400 shots. (Depending on energy and bullet weight)

Avoid setting too much hop with the first 2 magazines, as the patch must first work its way in. If possible, use a gas with a low silicone content, as this can greatly reduce the hop-up effect.

![EPeS O-Ring Set for WE G-Series / G-Force / G1X Magazines [E045-PZG-WE]](https://www.begadi.com/media/catalog/product/cache/a491986f8011072f66fb1fed37f51dcc/b/-/b-epes-e045-pzg-we-spare-seal-kit-gbb-mag-flange-we-glock-g.jpg)